Lean Gemba site visits at Salem Health

The Lean system at Salem Health combines strategy deployment and Lean fundamentals such as Visual Management, Huddles, 5S, Quick & Easy Kaizen and Standard Work.

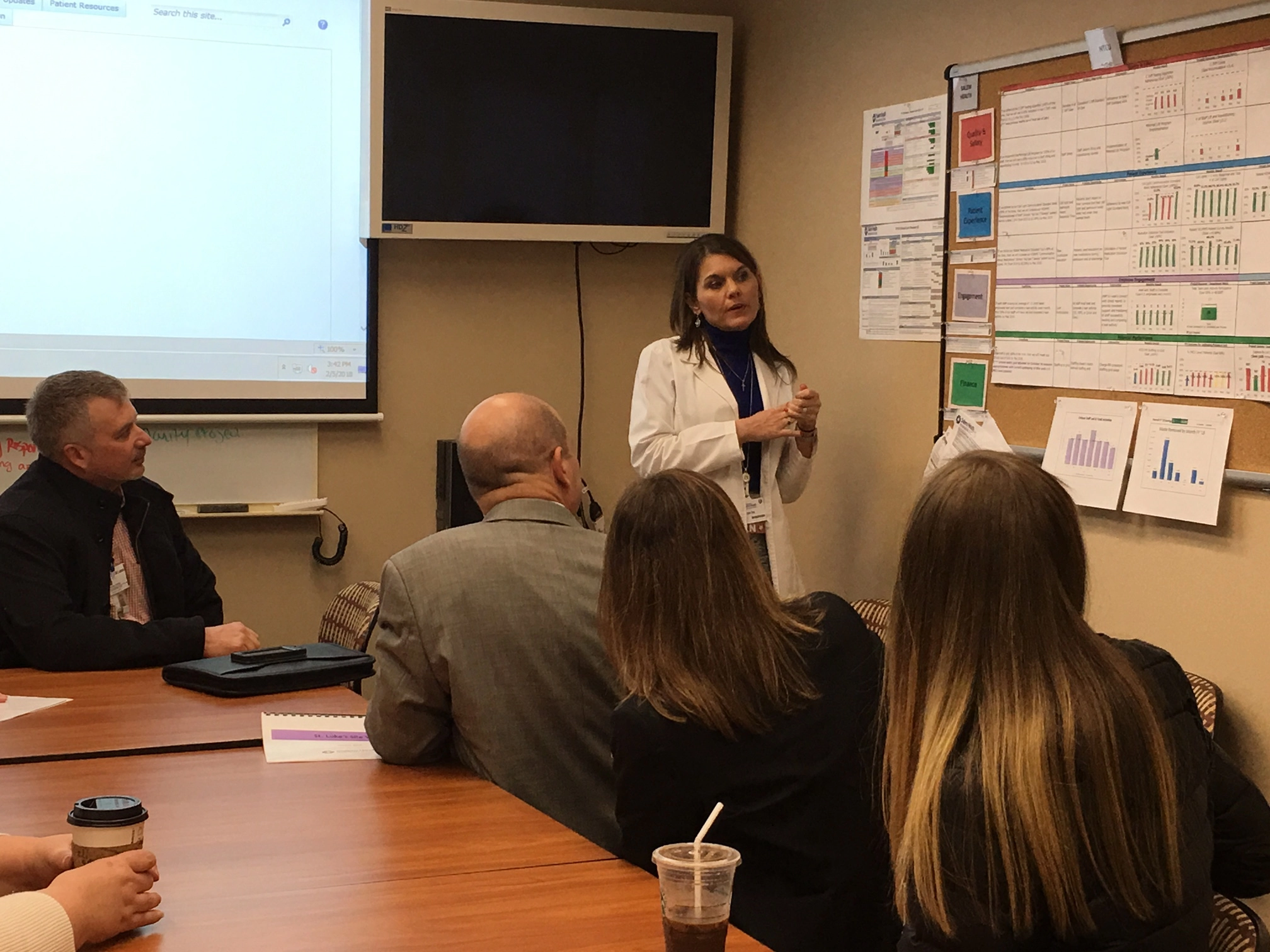

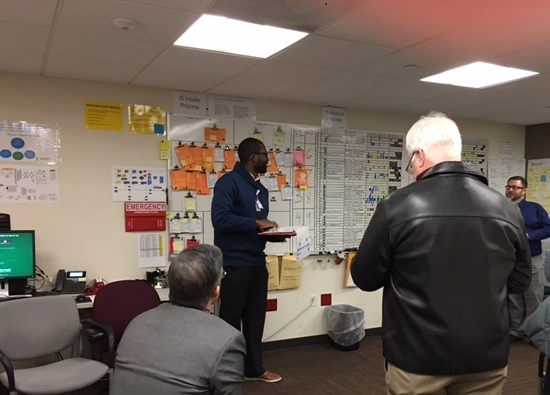

Guests at the Salem Health one-day Gemba tour will see the organization’s visibility room, learn about how staff and leaders are trained and developed in the Lean system, and discuss the Kaizen Promotion Office structure. Department Gemba tours will focus on how Lean fundamentals are deployed at the local level and how they promote alignment with organizational strategies.

For questions call Faith, the Kaizen Workflow Coordinator, at 503-814-3981.